Why MEP Drawings Are Treated as Secondary

By SWETHA K RAJANMEP Design Team Lead

By SWETHA K RAJANMEP Design Team Lead

1. How We Got Here

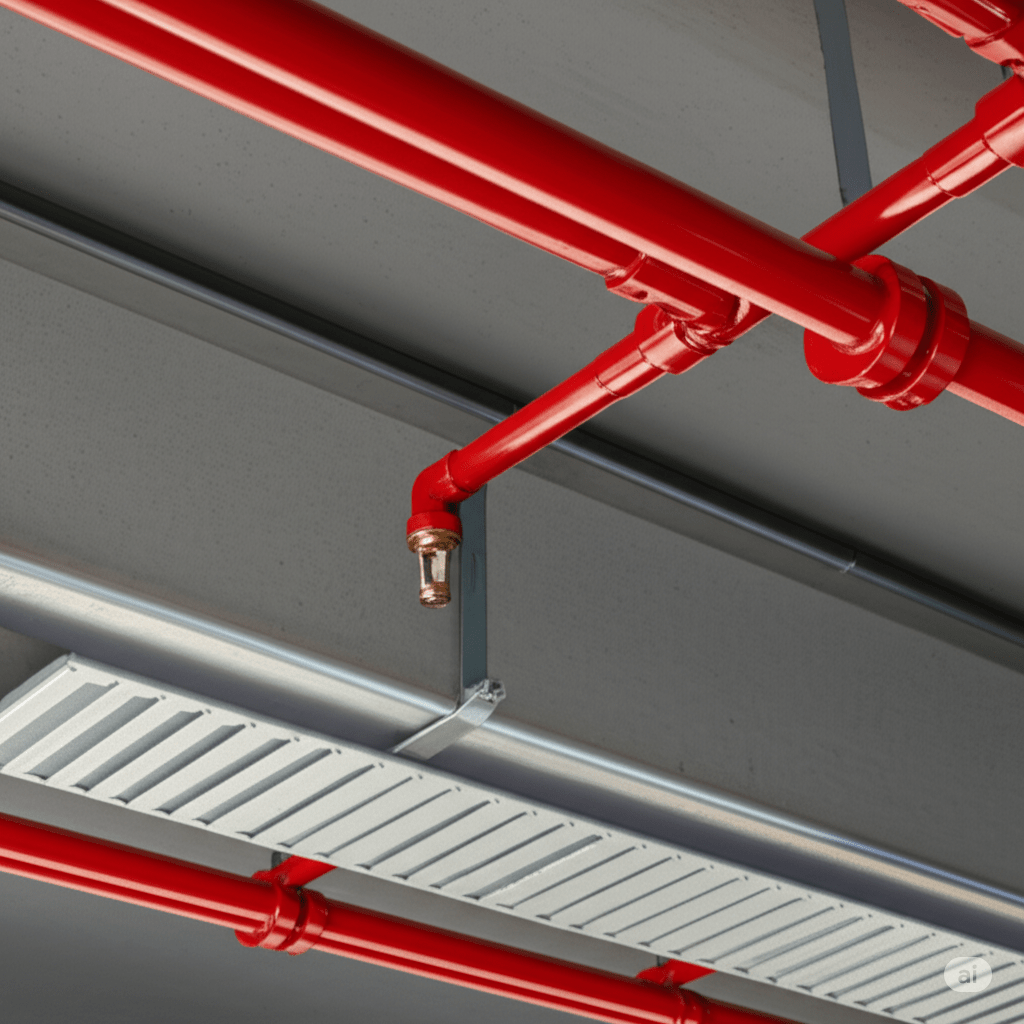

In the early stages of design, the focus is on form, façade, and floor area — things that are visually tangible. MEP systems, on the other hand, live behind walls and above ceilings. They're invisible until they fail.

So, decisions about shafts, plant rooms, and ceiling depths are often made without proper MEP input. By the time we're called in, the spaces are already boxed in — and we're expected to "make it fit."

It's not just frustrating. It's inefficient, costly, and sometimes even unsafe.

2. The Hidden Impact

When MEP design is treated as secondary:

- Service rooms shrink, forcing compromised layouts and poor maintenance access.

- Ceiling voids vanish, leading to duct clashes and rework.

- Energy efficiency suffers, because systems are adjusted around aesthetics instead of performance.

- Project costs rise, due to constant re-routing and redesigns late in the process.

What starts as a "minor coordination issue" often ends as a serious project delay.

3. The Real Reason Behind It

The problem isn't disrespect — it's visibility. Clients and architects can see an elevation or a façade. They can't visualize a chilled water pipe or a bus duct riser. Because MEP systems are complex, they often get postponed until "later" — when in reality, MEP should drive the layout just as much as columns and walls do.

The Visibility Problem

What isn't seen isn't valued. This is the core challenge facing MEP engineering today. Building services remain hidden until they malfunction, making it difficult for stakeholders to appreciate their critical role during design phases.

4. Changing the Culture

We can't wait for others to value MEP. We have to make it visible, understandable, and indispensable. Here's how we start:

Integrate early. Join concept discussions, not just coordination calls. Educate clients and architects on how early MEP inputs prevent redesigns.

Communicate visually. Use 3D visualizations, service zoning diagrams, and simple system narratives that non-engineers can relate to. Modern BIM coordination tools make this easier than ever.

Speak in project language, not just technical terms. Instead of saying "duct routing issue," say "if we shift this duct 150 mm, we save 2 false ceiling levels across all floors."

Own the coordination. Don't just mark clashes — suggest smart alternatives. When you solve problems proactively, you earn a seat at the decision table.

5. The Mindset Shift

The real transformation happens when MEP designers stop working under architecture and start working with it.

Because buildings don't live through their façades — they live through their systems. Air, water, power, comfort — that's MEP engineering. It's not secondary. It's the building's lifeline.

6. Final Thought

The next time someone says, "Just adjust the MEP," remind them gently — it's not an adjustment. It's engineering that keeps the architecture alive.

The culture won't change overnight. But every project where we advocate early, communicate clearly, and demonstrate value is a step toward recognition. MEP design isn't about fitting into leftover spaces — it's about creating efficient, sustainable, and functional buildings.

Start the conversation. Challenge the hierarchy. Make MEP visible.